Recommended minimum distance between hole slot edge to bend in sheet metal design is three times the sheet thickness plus bend radius.

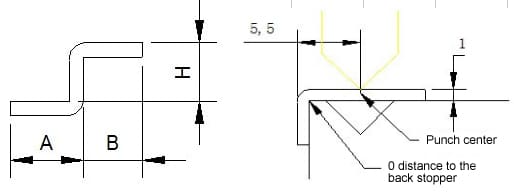

Minimum distance between two bends sheet metal.

Usually the preferred distance between holes and a bend is 1 5 times the sheet.

The minimum distance between one dimple and another is four times the material thickness plus the inside radius of each dimple.

It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii.

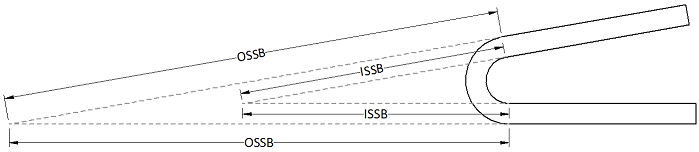

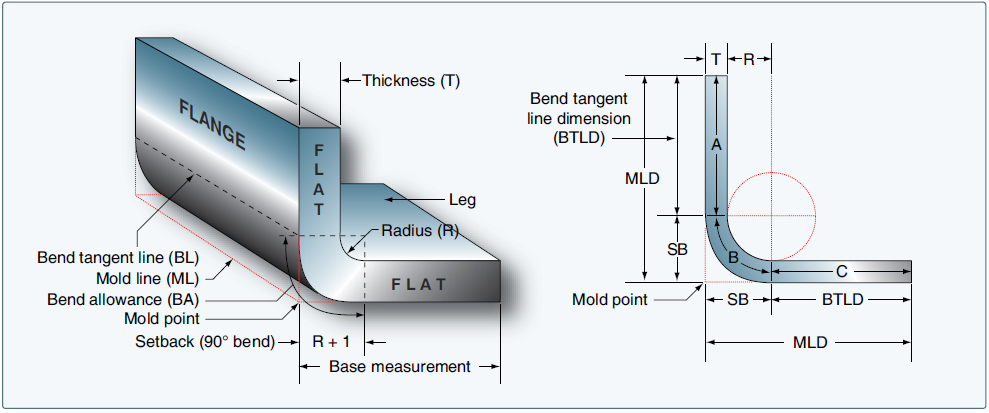

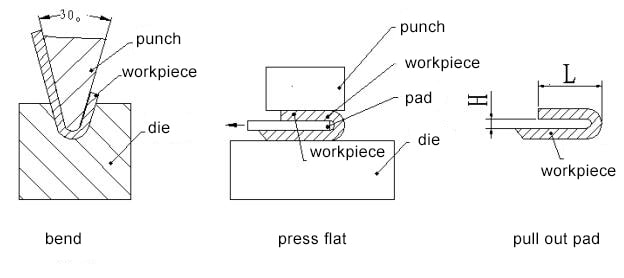

Bending size shown in the following picture.

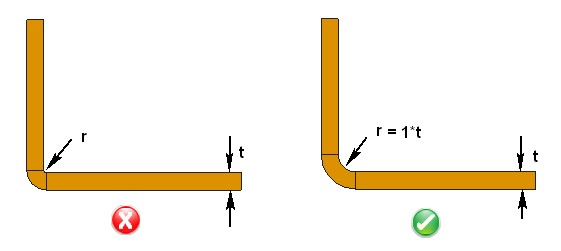

Minimum sheet metal bending radius.

The sheet metal design rule of thumb in this case is.

Also spaces between pierced holes and bends should accommodate the bend radius h and be far enough from the bend.

The minimum distance between two counterbores is eight times the material thickness.

For bends the minimum distance between the inside edge of the bend and the outside of the hem should be 5 times material thickness plus bend radius plus hem radius.

The minimum distance from a counterbore to an edge is four times the material thickness.

The minimum distance from a weld to a form is the spot diameter plus the bend radius.

The minimum distance between welds is 10 times the material thickness.

The more ductile the sheet metal the.

Use pems instead of threaded inserts.

The distance between the sheet metal bend line and edge of the hole should be two times or greater the thickness of the sheet metal.

Center to center distance between two holes minimum center to center distance between two holes in sheet metal parts is required to avoid metal distortion deformation and fracturing.

Using 20 times the material thickness is ideal.

Distance from outside mold line to the bottom of the cutout should be equal to the minimum flange length prescribed by the air bend force chart.

Whenever a increases by 1mm b increases 1 87 accordingly.

Sheet metal design consideration dimple.

For open hem the bend will lose its roundness when the inside diameter is greater than the sheet metal thickness.

3 reduction formula empirical value of gooseneck punch 0 5mm sheet.

In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm 0 03 inch whichever is larger counterbores.

A 7 67 b 0 5 minimum l bending 3 0.

The minimum distance between a weld and the edge is two times the diameter of the spot weld.

Use this document to choose values that are both manufacturable and meet your needs.

The minimum distance that a dimple should be from a bend is two times the material thickness plus the inside radius of the dimple plus the radius of the bend.

Bend radii minimum bend sizes.